Oil & Gas industries require parts with very high precision and workmanship. We have a dedicated team to take care of secondary process after machining. Raw material and finished part requires Traceability to very high level, which is maintained with our robust system.

Infrastructure

High Precision Engineering Division has the facilities for development and manufacture of new products and process. Adoption of new technologies to meet customer needs in areas like., identification of low cost alternate materials, surface finishing techniques, Environmental Requirement & Standardisation using Value Engineering.

The array of machines include Brother & Fanuc VMC’s has the capacity to maintain repeatability of very close tolerance. The CMM’s from Ziess can measure the profile of surfaces & touch scanning. The Clean Room ensures the Assembly and testing Critical medical assemblies to meet customer requirements. For Cleaning & Inspection of Critical Medical / Aerospace components, Ultrasonic cleaning equipment & Ultra Voilet inspection equipment were used.

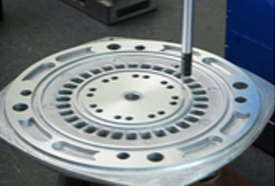

Co-ordinate Measuring Machine (CMM)

Co-ordinate Measuring Machine (CMM)

Height Measuring System (HMS)

Machine Shop

Quality Assurance

One of the factors that makes products and components from Roots HPED gain acceptance from diverse industries across the world, is the fact that quality assurance is completely controlled by the group’s in-house capabilities. From metrology, to tool and die making to machining, allied divisions of the Roots group take on critical tasks of the design and manufacturing process, thereby ensuring standards are consistently met and that precision is delivered.

Clientele

Supplying Parts to component manufactures of Major Oil & Gas Industries located in India, USA.