ROOTS a strategic supplier to well known Medical Equipment Manufacturers, believes in key values of Customer, follows spirit and Strategic Supplier Alliance Agreements. Prior experience in working with transfers close to 400 parts; we have good production facilities and knowledge to produce parts, Small Level Assemblies, High Level Assemblies & Ready fit modules.

Infrastructure

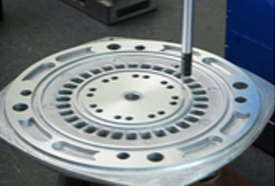

High Precision Engineering Division has the facilities for development and manufacture of new products and process. Adoption of new technologies to meet customer needs in areas like., identification of low cost alternate materials, surface finishing techniques, Environmental Requirement & Standardisation using Value Engineering.

The array of machines include Brother & Fanuc VMC’s has the capacity to maintain repeatability of very close tolerance. The CMM’s from Ziess can measure the profile of surfaces & touch scanning. The Clean Room ensures the Assembly and testing Critical medical assemblies to meet customer requirements. For Cleaning & Inspection of Critical Medical / Aerospace components, Ultrasonic cleaning equipment & Ultra Voilet inspection equipment were used.

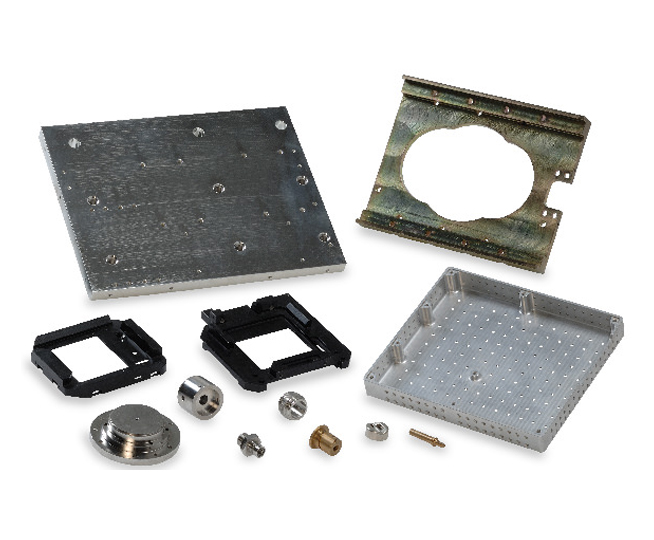

High Level Assembly

Small Level Assembly

Plastic Machined Parts

Aluminum & Steel Machined Parts

Quality Assurance

One of the factors that makes products and components from Roots HPED gain acceptance from diverse industries across the world, is the fact that quality assurance is completely controlled by the group’s in-house capabilities. From metrology, to tool and die making to machining, allied divisions of the Roots group take on critical tasks of the design and manufacturing process, thereby ensuring standards are consistently met and that precision is delivered.

Clientele

Supplying Parts, Small Level Assemblies, High Level Assemblies & Ready Fit Modules to Major Medical equipment manufacturers located in India, Sweden, USA etc.